Gear Reduction Systems Service & Repair

Tipton Engineering & Electric Motor Services, Inc. is your local expert in gear reduction system repairs. Our team of experienced technicians specializes in repairing machines that run large conveyors, agitators, cement mixers, and gearboxes. We understand how important it is to keep your equipment running smoothly, and we're here to help you get back up and running as quickly as possible. We are based in Sharpsville, IN, and proudly serve residential and commercial customers in the surrounding areas.

Gear Reduction System Repairs

We offer many services to help you with your gear reduction system repairs. These services include:

- Gearbox Repair & Rebuilds

- Bearing Replacements

- Shaft Repairs & Replacements

- Lubrication System Repairs

- Sealing System Repairs

We Get Your Machines Working Again

Our team has years of experience in the industry, and we're committed to providing you with the highest quality repairs and customer service. We understand that downtime can be costly for your business, so we work quickly and efficiently to get your equipment back up and running as soon as possible.

Gearbox Functions Include:

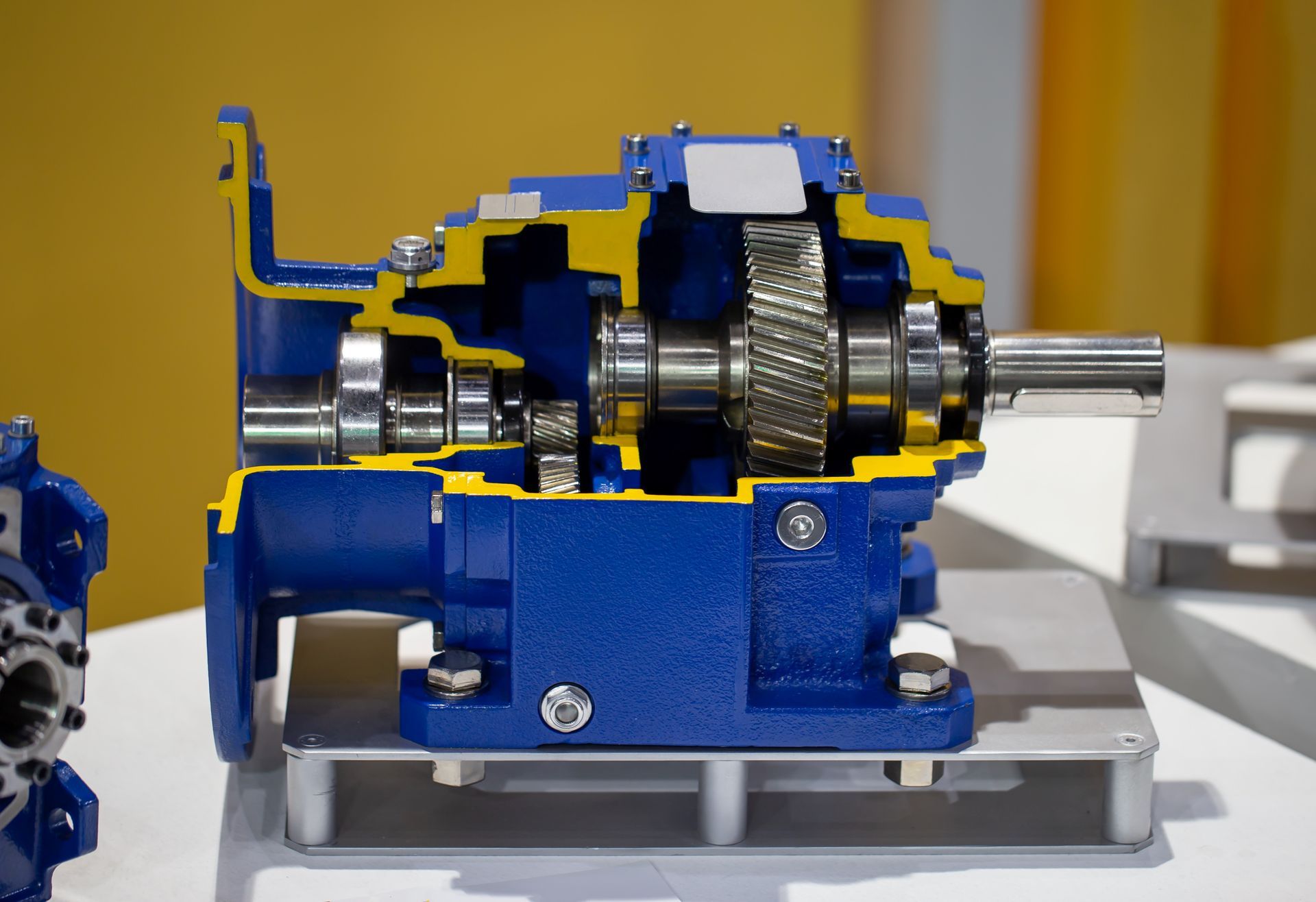

- Power Transmission: The primary function of a gearbox is to transmit power from a power source, such as an engine or motor, to an output device, such as wheels, conveyor belts, or other mechanical components. By meshing together gears of different sizes, gearboxes can transfer power efficiently while adjusting torque and speed.

- Speed Control: Gearboxes allow for the control of rotational speed. By changing the ratio of gear sizes, a gearbox can either increase or decrease the rotational speed of the output shaft relative to the input shaft. This is essential for matching the speed of the machinery to the requirements of the task at hand. For example, in an automobile, gears are shifted to maintain an optimal engine speed for various driving conditions.

- Torque Conversion: Gearboxes can also convert torque. Torque is the rotational force produced by the engine or motor. By altering gear ratios, gearboxes can increase torque output while decreasing rotational speed, or vice versa. This capability is essential for optimizing performance in different applications, such as heavy lifting equipment or vehicles climbing steep inclines.

- Directional Control: In some cases, gearboxes are used to control the direction of rotation. By incorporating additional gears and mechanisms, gearboxes can reverse the direction of rotation of the output shaft relative to the input shaft. This is crucial for machinery that requires reversible motion, such as winches or reversible conveyor belts.

Overall, gearboxes serve as versatile mechanical components that enable precise control over power transmission, speed, torque, and direction of rotation, making them indispensable in a wide range of industries and applications, including automotive, manufacturing, construction, and more.

Call Us Today

If you're experiencing issues with your gear reduction system, don't hesitate to contact us today at 765-963-3380. We're here to help you get your equipment running smoothly again.

BUSINESS INFORMATION

Phone: 765-963-3380

Address: 159 W. Vine St., Sharpsville, IN 46068

(Across from the Fire Station)

BUSINESS HOURS

- Mon - Fri

- -

- Sat - Sun

- Closed

PAYMENT OPTIONS

We accept payments through SQUARE